casting aluminum wheels

How do you cool a cast aluminum wheel?

Following a preset dwell time determined by computer controls, the various parts of the mold open hydraulically revealing the now hardened cast aluminum wheel inside. Robotic arms remove the wheel from the mold and place it immediately into a water quench to cool the casting.

Are alloy wheels forged?

Most of the alloy wheels on the market are one-piece cast wheels, not forged. The difference between the two processes is that casting involves placing liquefied aluminum into a mold. As the aluminum cools, it is formed into a wheel. There are several different ways to accomplish this, including gravity casting and low-pressure casting.

How are aluminum wheels made?

Aluminum wheels can be made by several different techniques. The most prevalent are casting, forging, and flow forming. Casting and forging are unique. Flow forming uses a combination of both. Cast wheels have somewhat of a bad reputation for ultimate strength, but that reputation was earned by poor quality wheels from substandard suppliers.

How is a cast wheel made?

A cast wheel is made by pouring molten aluminum into a mold where it is formed to the correct shape and sits there until it cools down. Once the wheel cools down, they perform trimming and drilling. Unfortunately, there is one massive flaw with this method of producing wheels: porosity.

Materials

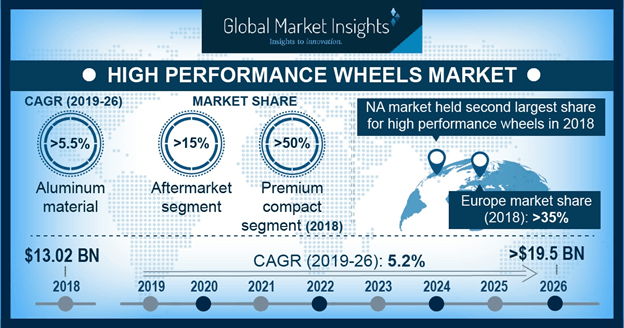

Aftermarket wheels were originally made from magnesium, hence the name “Mag” wheels. Currently they are made from several materials including steel, aluminum, exotic alloys, carbon fiber; even plastic. We will focus on aluminum as most aftermarket wheels are made from aluminum alloy. During your selection process, do some research into the weight r

Standards

Cheap, heavy wheels made with inferior practices or to nonexistent standards, can be less expensive, but are no bargain. Properly constructed wheels will perform much better. The processes used, and the attention to detail may increase costs, but are crucial to a quality final product. Look for wheels that are tested to accepted benchmarks, and hav

Techniques

Aluminum wheels can be made by several different techniques. The most prevalent are casting, forging, and flow forming. Casting and forging are unique. Flow forming uses a combination of both. Cast wheels have somewhat of a bad reputation for ultimate strength, but that reputation was earned by poor quality wheels from substandard suppliers. Cast w

Forging

The forging process for aluminum wheels uses heat and pressure to form the part. Unlike the cast part, the surface can be irregular, and require a machining process to get it smooth. Hot forging is common on larger, thicker parts that require more movement of the material. Forging a complex part may require multiple operations with progressive dies

Flow Forming

Flow forming has benefits of both the casting, and forging processes. The wheel begins to take shape as a casting. The wheel face is cast, taking on the smooth finish that makes a casting precise, and cost effective. The casting is then heated and put on a turning die. While the part spins, hydraulically controlled tooling puts pressure on the part

Making aluminium alloy wheel using permanent mold

How Its Made

Hypnotic production process of alloy wheels by casting method and truck wheels by welding method

|

Manufacturing Processes of Car Alloy Wheels

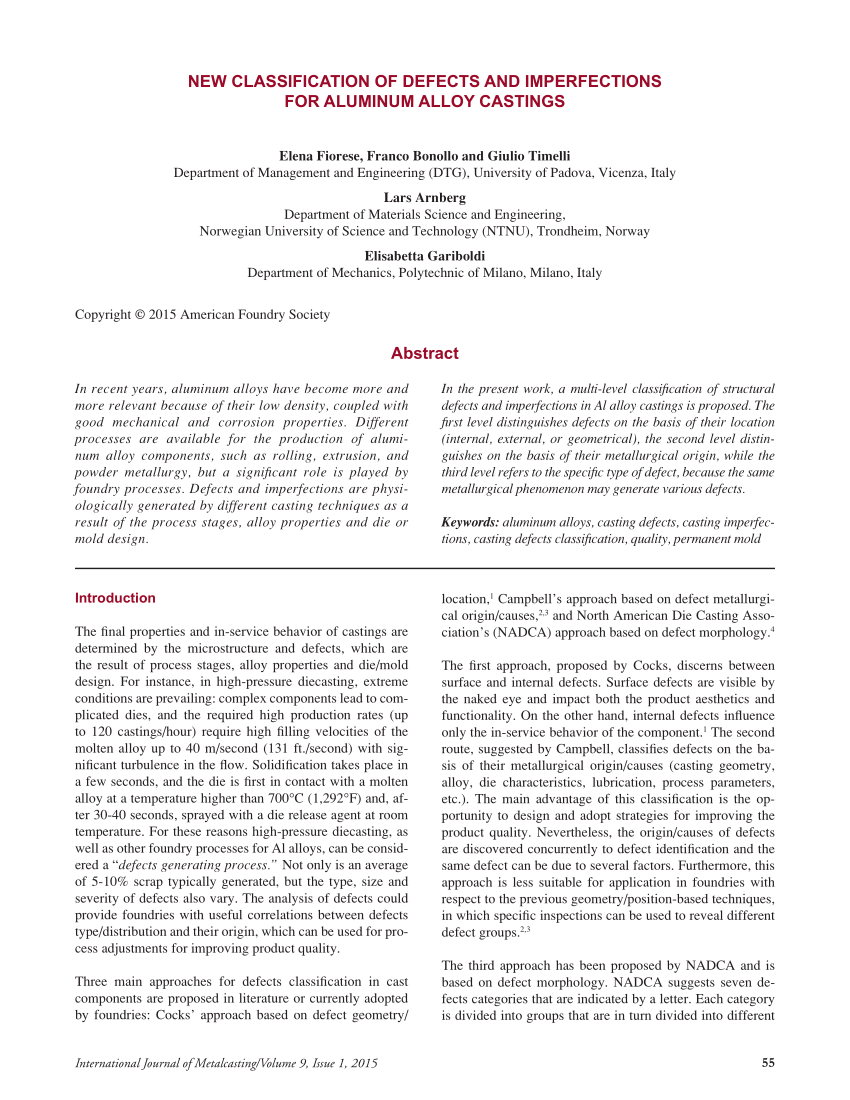

30 Jul 2022 Temperature distributions of mold during the casting process [22]. 2-2 Casting defects in low-pressure die-cast aluminum alloy wheel. Defects in ... |

|

Dynalook

Section 2 presents the material characterization of the aluminum alloy of which the wheel is made. Coupons were directly extracted out of different locations |

|

European Aluminium

As a result both cast and forged aluminium wheels are finally machined. Compared to steel wheels |

|

Fatigue Life Analysis of Aluminum Wheels by Simulation of Rotary

Tables 1 and 2 show the components of A356 cast aluminum alloy and the mechanical performance of these components [9]. 2.2 Foundry Technology. Gravity casting |

|

ALUMINUM ALLOY WHEELS CASTING

ALUMINUM ALLOY WHEELS CASTING. INVESTMENT OPPORTUNITY SCORECARD. MINING & METALS. Page 2. 2. Aluminum Alloy Wheels Casting. MINING & METALS. High Potential. |

|

Episode 9: Aluminum vs. Steel Wheels – An Age-Old Debate

aluminum wheels. We'll be talking about the differences between forged aluminum wheels and cast aluminum wheels. This is sort of our wheelhouse for pun ... |

|

Research on Integrated Casting and Forging Process of Aluminum

2 Jul 2014 of the aluminum alloy wheels. Chen and Li [4] investigated mechanical ... of predictive control for aluminum wheel casting via a virtual. |

|

Casting defects in low-pressure die-cast aluminum alloy wheels

As a result most new North American cars are equipped with cast aluminum wheels.1 Within the wheel industry |

|

Aluminum Car Wheel Molding Methods and Numerical Simulation of

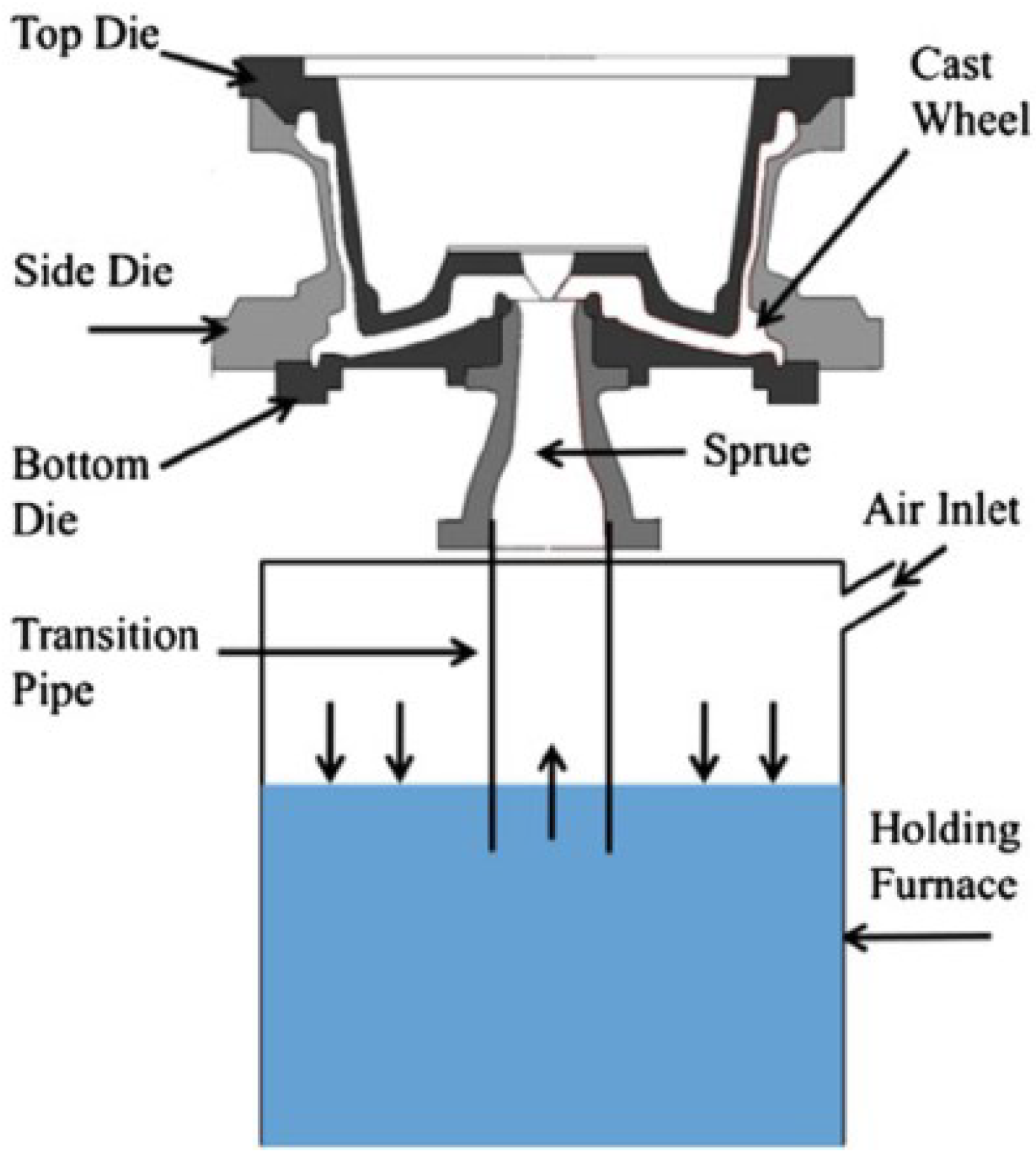

squeeze casting of aluminum wheels. Simulation the Process of Extrusion Casting Aluminum Alloy Car Wheel Molding. Fig.1 is the three-dimensional model of a |

|

Failure analysis of aluminum alloys casting in four- wheels vehicle

Abstract. The small industry of casting aluminum alloy produces four-wheeled motorized tire rims that have been used in various vehicles. |

|

Manufacturing Processes of Car Alloy Wheels

30 juil. 2022 Keywords: Alloy wheels Casting |

|

Folie 1

Highly Efficient Manufacturing of Steel and Aluminum Wheels. WHEEL SPINNING CENTER – APPLICATIONS Forming Principle for Cast or Forged Aluminum Wheels. |

|

Dynalook

Wheels may be subjected to severe loading in case of a vehicle crash and often play representative cast aluminum wheel of 16” has been characterized and ... |

|

Fatigue Life Analysis of Aluminum Wheels by Simulation of Rotary

2.2 Foundry Technology. Gravity casting and low-pressure casting are the two major approaches to case aluminum alloy wheels. Gravity casting presses molten |

|

Defect Detection of Aluminum Alloy Wheels in Radiography Images

23 nov. 2018 Abstract: In low-pressure casting aluminum alloy wheels are prone to internal defects such as gas holes and shrinkage cavities |

|

European Aluminium

1970s cast aluminium wheels started to be factory-fitted to mass-produced cars. Aluminium penetration in wheels was in the year 2000 for European vehicles |

|

Numerical simulation of low pressure die-casting aluminum wheel

the application of light-weight aluminum alloy castings for various components that previously made from steels or cast irons for example |

|

Cast Aluminum Wheels for Trucks and Buses — Testing and

CAST ALUMINUM ALLOY VEHICLE WHEELS offer aside from interesting styling possibilities |

|

Failure analysis of aluminum alloys casting in four- wheels vehicle

Abstract. The small industry of casting aluminum alloy produces four-wheeled motorized tire rims that have been used in various vehicles. |

|

Cast aluminum alloy compressor wheel for a turbocharger

26 juil. 2017 [0001] The present invention relates to a compressor wheel made of a cast aluminum alloy for use in a turbocharger. |

|

Numerical simulation of low pressure die-casting aluminum wheel

Low-pressure die casting (LPDC) process is a near net shape casting method [3] Due to the high precision and high efficiency requirements as well as its capacity |

|

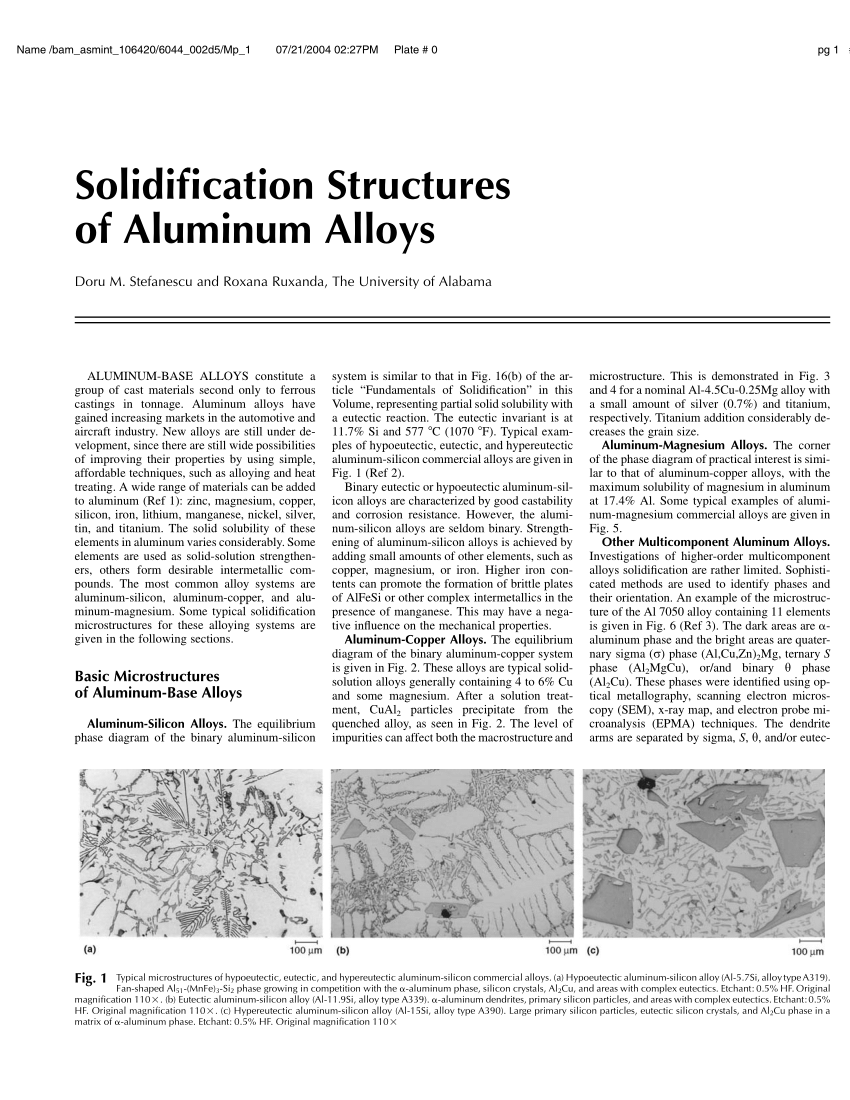

Use of simulation in the production of cast aluminium wheels Bernd

Production of a cast wheel starts with the melting of the charge material and a usual melt treatment In general, AlSiMg with T6 heat treatment and AlSi11 |

|

Casting defects in low-pressure die-cast aluminum alloy wheels

Owing to its ability to produce high- quality wheels in a cost-effective manner, the dominant process for casting alumi- num alloy wheels is the low-pressure die- |

|

Applications – Chassis & Suspension – Wheels - European Aluminium

Almost all modern aluminium wheels are made by one of two processes: casting and forging Their performance is a direct result of the employed manufacturing |

|

Optimization of Casting Defects in Aluminum Alloy Wheels - Neliti

Aluminum casting alloy wheels are generally produced using low-pressure die-casting For the application of this casting method, Al-Si casting alloys should be chosen owing to their high adaptation capability to the permanent metal molds |

|

Minimization of Casting Defects in Aluminum Alloys Wheels - IRJET

The production of aluminum alloy wheels are generally produced by lower pressure die casting for applying this as casting method the Al-Si casting alloy should |

|

Casting Simulation of Automotive Wheel Rim Using Aluminium Alloy

Aluminium wheel rims used in transport vehicles are commonly produced by gravity die casting In Industries it is been a research issue for improving the quality |

|

Minimization of Defect in Aluminium Alloy Wheel Casting - IJSER

To produce good quality aluminum cast wheels, defects must be minimized Aim of the current study is to study defects of an aluminum alloy casting and to |

![PDF] Numerical simulation of low pressure die-casting aluminum PDF] Numerical simulation of low pressure die-casting aluminum](https://imgv2-1-f.scribdassets.com/img/document/254248020/298x396/d3ffb3b219/1554988277?v\u003d1)

![PDF] Numerical simulation of low pressure die-casting aluminum PDF] Numerical simulation of low pressure die-casting aluminum](https://0.academia-photos.com/attachment_thumbnails/31713998/mini_magick20190426-1470-ywsed3.png?1556262951)

![PDF] Numerical simulation of low pressure die-casting aluminum PDF] Numerical simulation of low pressure die-casting aluminum](https://www.mdpi.com/metals/metals-10-00563/article_deploy/html/images/metals-10-00563-g016.png)