disadvantages of chemical treatment

Why is chemical sludge dangerous?

The addition of chemicals also results in the production of a large volume of sludge that will need to be treated and disposed of following treatment. This sludge is also hazardous due to the nature of the constituents being added. The volume and toxicity of the sludge can drive up disposal costs as its not easily dewatered.

What are the common pitfalls in choosing a chemical coagulation water treatment system?

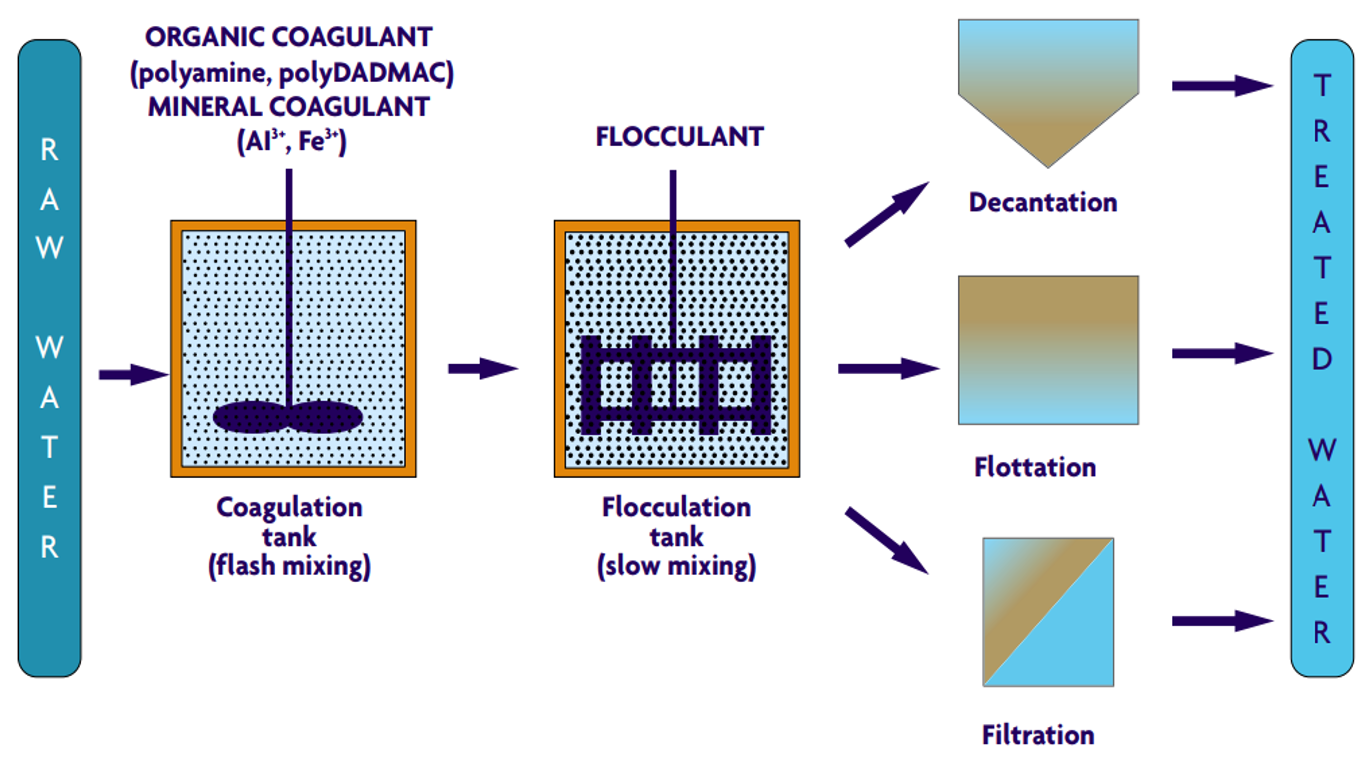

We will discuss below seven common pitfalls in choosing a chemical coagulation water treatment system for your municipal or industrial water treatment process. One of the most prevalent and obvious disadvantages to any type of coagulation process is the resulting sludge.

What are the disadvantages of chemical coagulation?

One of the most prevalent and obvious disadvantages to any type of coagulation process is the resulting sludge. As the suspended solids cluster together and fall, they gather at the bottom of the tank. In a chemical coagulation water treatment process, the volume of the sludge produced can be significant.

What are the disadvantages of sludge treatment?

In addition to the need for the high dosage to get optimal pH, there are some drawbacks, such as relatively large volumes of sludge leading to dewatering, disposal issues, amphoteric, and the inhabitation of metal hydroxide precipitation with the presence of complexing agents.

on This Page

Granular activated carbonPacked tower aerationMulti-stage bubble aerationAnion exchange epa.gov

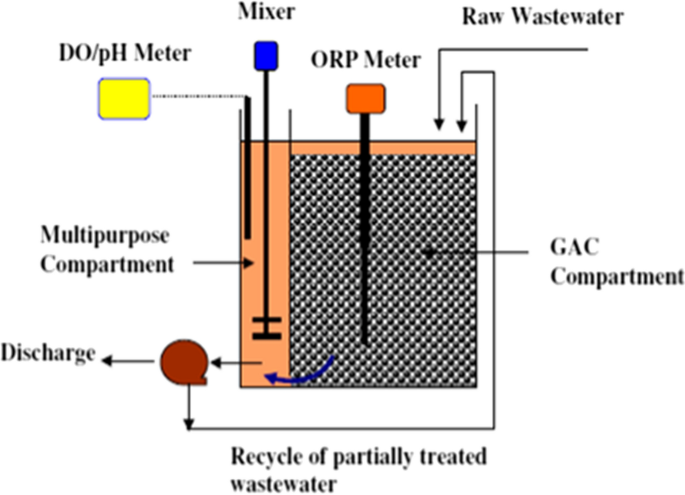

Granular Activated Carbon

What is granular activated carbon? Granular activated carbon (GAC) is a porous adsorption media with extremely high internal surface area. GACs are manufactured from a variety of raw materials with porous structures including: 1. bituminous coal 2. lignite coal 3. peat 4. wood 5. coconut shells Physical and/or chemical manufacturing processes are applied to these raw materials to create and/or enlarge pores. This results in a porous structure with a large surface area per unit mass. Why is it useful? GAC is useful for the removal of taste- and odor-producing compounds, natural organic matter, volatile organic compounds (VOCs), synthetic organic compounds and disinfection byproduct precursors. Organic compounds with high molecular weights are readily adsorbable. Treatment capacities for different contaminants vary depending on the properties of the different GACs, which in turn vary widely depending on the raw materials and manufacturing processes used. What are the advantages of using GAC? GAC is a proven technology with high removal efficiencies (up to 99.9%) for many VOCs, including trichloroethylene (TCE) and tetrachloroethylene (PCE). In most cases, GAC can remove target contaminants to concentrations below 1 µg/l. Another advantage is that regenerative carbon beds allow for easy recovery of the adsorption media. epa.gov

Packed Tower Aeration

What is packed tower aeration? Aeration processes, in general, transfer contaminants from water to air. Packed tower aeration (PTA) uses towers filled with a packing media designed to mechanically increase the area of water exposed to non-contaminated air. Water falls from the top of the tower through the packing media while a blower forces air upwards through the tower. In the process, volatile contaminants pass from the water into the air. Why is it useful? PTA is useful for removing volatile contaminants including: 1. Volatile organic compounds (VOCs) 2. Disinfection byproducts 3. Hydrogen sulfide 4. Carbon dioxide 5. Other taste- and odor-producing compounds The more volatile the contaminant, the more easily PTA will remove it. PTA readily removes the most volatile contaminants, such as vinyl chloride. With sufficient tower height and air flow, PTA can even remove somewhat less volatile contaminants, such as 1,2-dichloroethane. What are the advantages of using PTA? PTA is a proven technology and can achieve high removal efficiencies (99 percent or greater) for most VOCs. PTA removal efficiency is independent of starting concentration. Therefore, it can remove most volatile contaminants to concentrations below 1 µg/L. PTA generates no liquid or solid waste residuals for disposal. epa.gov

Multi-Stage Bubble Aeration

What is multi-stage bubble aeration? Aeration processes, in general, transfer contaminants from water to air. Multi-stage bubble aeration (MSBA) uses shallow basins that are divided into smaller compartments, or stages, using baffles. Inside each stage, diffusers (consisting of perforated pipes or porous plates) release small air bubbles that rise through the water. The bubbles and their resulting turbulence cause volatile contaminants to pass from the water into the air. Why is it useful? MSBA is useful for removing volatile contaminants including: 1. Volatile organic compounds (VOCs) 2. Hydrogen sulfide 3. Carbon dioxide 4. Other taste- and odor-producing compounds The more volatile the contaminant, the more easily MSBA will remove it. Vendors supply MSBA in skid-mounted, pre-packaged systems that can be particularly suitable for small systems. What are the advantages of using MSBA? MSBA is a proven technology. In recent EPA pilot tests, MSBA achieved high removal efficiencies (98 percent to greater than 99 percent) for most VOCs, removing them to concentrations below 1 µg/L. MSBA is a low-profile aeration technology that does not require tall, potentially unsightly towers. MSBA generates no liquid or solid waste residuals for disposal. epa.gov

Anion Exchange

What is anion exchange? In an anion exchange treatment process, water passes through a bed of synthetic resin. Negatively charged contaminants in the water are exchanged with more innocuous negatively charged ions, typically chloride, on the resin’s surface. Why is it useful? Anion exchange is useful for the removal of negatively charged contaminants including arsenic, chromium-6, cyanide, nitrate, perchlorate, per- and polyfluoroalkyl substances (PFAS), sulfate, and uranium. Treatment capacities for different contaminants vary depending on the properties of the resin used and characteristics of the influent water. Several of vendors manufacture different resins, including those designed to selectively remove specific contaminant ions. What are the advantages of using anion exchange? Anion exchange is a proven technology that can achieve high removal efficiencies (greater than 99 percent) for negatively charged contaminants. When the capacity of the resin is exhausted, it can be regenerated to restore it to its initial condition. The regeneration process uses a saturated solution, usually of sodium chloride (also known as brine). An alternative to regeneration is to dispose of the exhausted resin and replace it with fresh resin. This alternative is often employed when sel

Cation Exchange

What is cation exchange? In a cation exchange treatment process, water passes through a bed of synthetic resin. Positively charged contaminants in the water are exchanged with more innocuous positively charged ions, typically sodium, on the resin’s surface. Why is it useful? Cation exchange is useful for water softening by removing hardness ions such as calcium and magnesium. It can also remove other positively charged contaminants including barium, radium and strontium. Treatment capacities for different contaminants vary depending on the properties of the resin used and characteristics of the influent water. A number of vendors manufacture different resins, including those designed to selectively remove specific contaminant ions. What are the advantages of using cation exchange? Cation exchange is a proven technology for water softening and removal of positively charged contaminants. It can achieve high removal efficiencies (greater than 99 percent) for positively charged contaminants. When the capacity of the resin is exhausted, it can be regenerated to restore it to its initial condition. The regeneration process uses a saturated solution, usually of sodium chloride (also known as brine). epa.gov

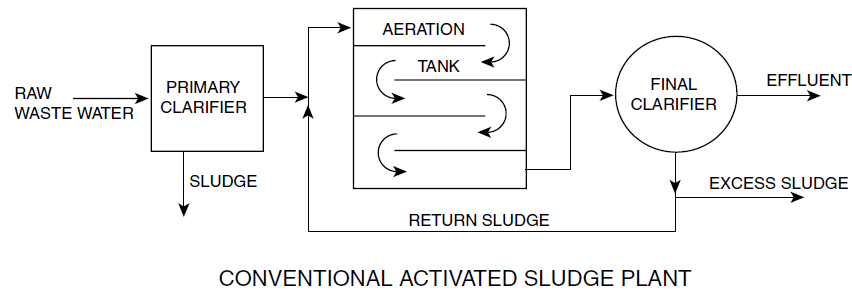

Biological Treatment

What is biological treatment? Biological treatment of drinking water uses indigenous bacteria to remove contaminants. The process has a vessel or basin called a bioreactor that contains the bacteria in a media bed. As contaminated water flows through the bed, the bacteria, in combination with an electron donor and nutrients, react with contaminants to produce biomass and other non-toxic by-products. In this way, the biological treatment chemically “reduces” the contaminant in the water. Why is it useful? Biological treatment is useful for the removal of contaminants including nitrate and perchlorate. Following a startup period, the bacterial population in the water will adapt to consume the target contaminants as long as favorable conditions, such as water temperature and electron donor and nutrient concentrations, are maintained. What are the advantages of using biological treatment? Biological treatment can achieve high removals (greater than 90 percent) of nitrate and perchlorate. The process destroys contaminants, as opposed to removing them, and, therefore, does not produce contaminant-laden waste streams. Biological treatment remains effective even in the presence of certain co-occurring contaminants. epa.gov

Reverse Osmosis/Nanofiltration

What are reverse osmosis and nanofiltration? Reverse osmosis (RO) and nanofiltration (NF) are membrane separation processes that physically remove contaminants from water. These processes force water at high pressure through semi-permeable membranes that prevent the passage of various substances depending on their molecular weight. Treated water, also known as permeate or product water, is the portion of flow that passes through the membrane along with lower molecular weight substances. Water that does not pass through the membrane is k

Adsorptive Media

What is adsorptive media? Adsorptive water treatment technologies involve passing contaminated water through a media bed. The contaminants in the water adsorb to empty pore spaces on the surface of the adsorptive media as the water passes through. Granular activated carbon (GAC), described above, is one type of adsorptive media, but other types exist, including aluminum-based, iron-based, titanium-based, zirconium-based and other types of media. Why is it useful? Adsorptive media treatment is useful for removal of inorganic contaminants including antimony, arsenic, beryllium, fluoride, selenium, thallium, and uranium. The capacity of the media to adsorb different contaminants depends on the specific type of media used, the water chemistry (e.g., pH), and contaminant valence. What are the advantages of using adsorptive media? Adsorptive media is a proven technology with high removal efficiencies for certain inorganic contaminants (e.g., up to greater than 99% for arsenic, up to 99% or more for fluoride). When the appropriate media is used in combination with the appropriate water quality conditions (e.g., pH), the process can remove selected target contaminants to concentrations below relevant regulatory limits. Another advantage is that some types of adsorptive media can be regenerated in place after their capaci

Ultraviolet Photolysis and Advanced Oxidation Processes

What is ultraviolet photolysis and advanced oxidation? Ultraviolet (UV) light can be used on its own (in photolysis), or in combination with chemical addition (in UV advanced oxidation), to reduce the concentration of organic contaminants. In UVAOP drinking water treatment, water passes through a reactor vessel equipped with lamps that emit UV light. In photolysis, the contaminants are degraded by the photons emitted by the UV lamps. Advanced oxidation adds chemicals such as hydrogen peroxide (H2O2) or chlorine. These chemicals react with the UV

|

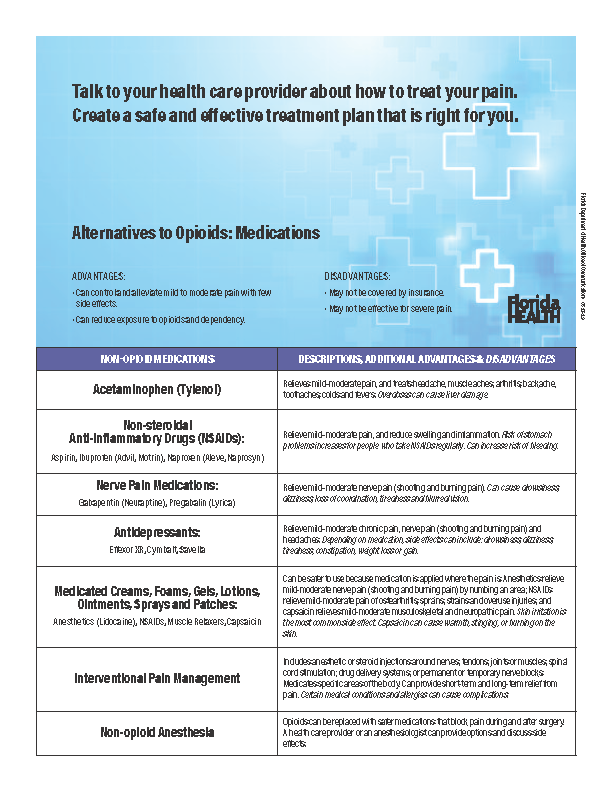

Advantages and disadvantages of techniques used for wastewater

٢٨/٠٣/٢٠١٩ Cur- rent wastewater treatment methods involve a combination of physical chemical and biological processes |

|

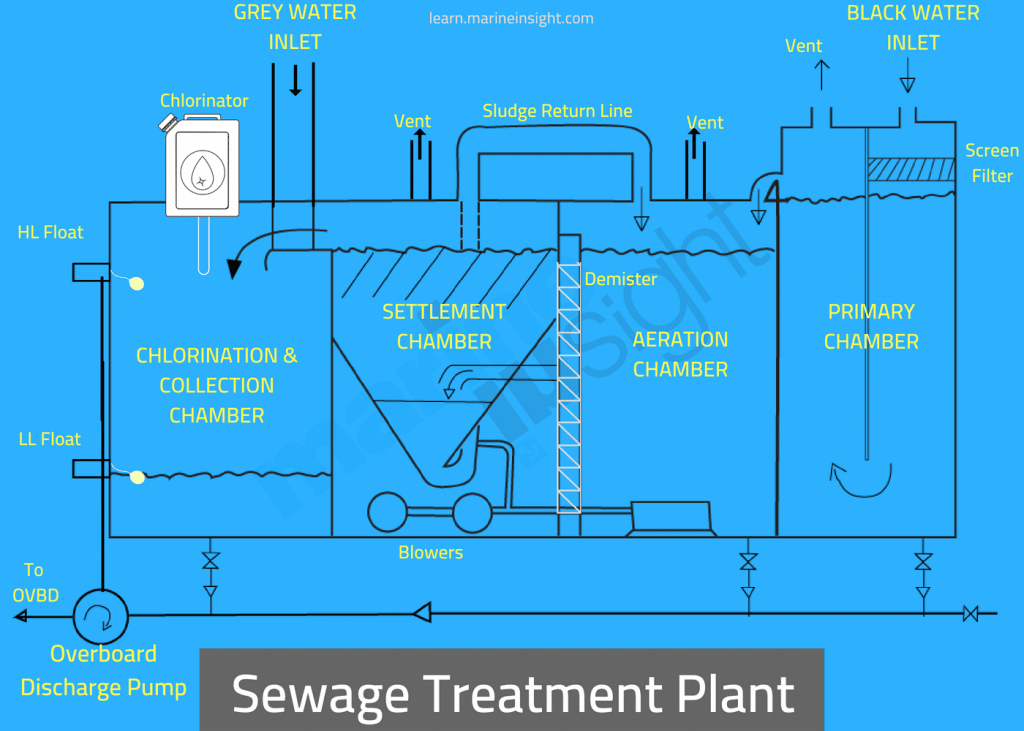

Wastewater Technology Fact Sheet: Chlorine Disinfection

The treatment plant also had to optimize chemical usage with the continued increase in chemical costs. The original chlorine dose was 15 mg/L where 5 to. 6 |

|

Hazardous Waste Treatment Advantages & Regulatory Pitfalls

▫ Chemical Character;. ▫ Biological Character; or. ▫ Composition of a Hazardous 3.3.2 Advantages & Disadvantages of. Compactor Treatment. ▫ Advantages ... |

|

Comparison and analysis of several medical waste treatment

advantages and disadvantages of incineration treatment pressure steam treatment |

|

Advantages and Disadvantages of Plasma Treatment of Textile

٠٩/٠٨/٢٠١٣ These K/S values show successful surface dying of PP fabrics. Page 2. 21st International Symposium on Plasma Chemistry (ISPC 21). Sunday 4 ... |

|

Recent Advances on Coagulation-Based Treatment of Wastewater

Purpose of Review The use of conventional chemical coagulant in treatment of wastewater is gaining great attention. Drawbacks related to the prolonged effects |

|

Phosphorus Removal and Recovery from Wastewater using Magnetite

Disadvantages of chemical precipitation As was described above present treatment methods have some advantages but also a lot of disadvantages. |

|

Review on Chemical treatment of Industrial Waste Water * O.P.

The inherent disadvantage to this process is the generation of large quantities of chemical sludge and its classification as hazardous waste necessitating |

|

Engineering Chemistry UNIT-1-WATER CHEMISTRY

treatment of boiler water. •. By maintaining pH value of water and • Disadvantages: If excess chlorine is added it leave residual or free chlorine which ... |

|

Wastewater Technology Fact Sheet: Dechlorination

For treatment plants that must discharge a zero Effective process control will help prevent chemical overdosing and allow for chemical cost savings. |

|

Advantages and disadvantages of techniques used for wastewater

28 mars 2019 Cur- rent wastewater treatment methods involve a combination of physical chemical and biological processes |

|

Recent Advances on Coagulation-Based Treatment of Wastewater

Transition from chemical to natural coagulant can be a good strategy to reduce the aforementioned drawbacks. Therefore this review aims to provide critical |

|

Nutrient Removal (P-Removal) at Wastewater Treatment Plant May

Chemical P-Removal has the following general advantages and disadvantages worth considering: ? Advantages: No modification to biological process; |

|

MODELLING OF COAGULANT DOSAGE IN A WATER TREATMENT

Disadvantages associated with jar testing are the necessity to perform manual Water treatment involves physical chemical and biological processes that ... |

|

Decontamination Techniques Used in Decommissioning Activities

waste the treatment and disposal of which would result in excessive requirements The main disadvantage of chemical decontamination is the generation of ... |

|

Advantages and Disadvantages of Plasma Treatment of Textile

9 août 2013 The textile industry not only is one of the most energy intensive industries but also uses tremendous amounts of chemicals and water in textile ... |

|

ADVANTAGES AND DISADVANTAGES OF CHEMICAL METHODS

8 janv. 2020 Thus the gel obtained is subjected to the drying process and the resulting product is transformed into xerogel |

|

Wastewater treatment: an overview

12 mars 2019 chemical and biological contamination of water have become a major concern ... the advantages and disadvantages of technologies available. |

|

Electrochemical treatment of highly concentrated wastewater: A

5 déc. 2020 properties define the type of treatment and thus the chemical and ... Their main drawbacks lie in the production of secondary. |

|

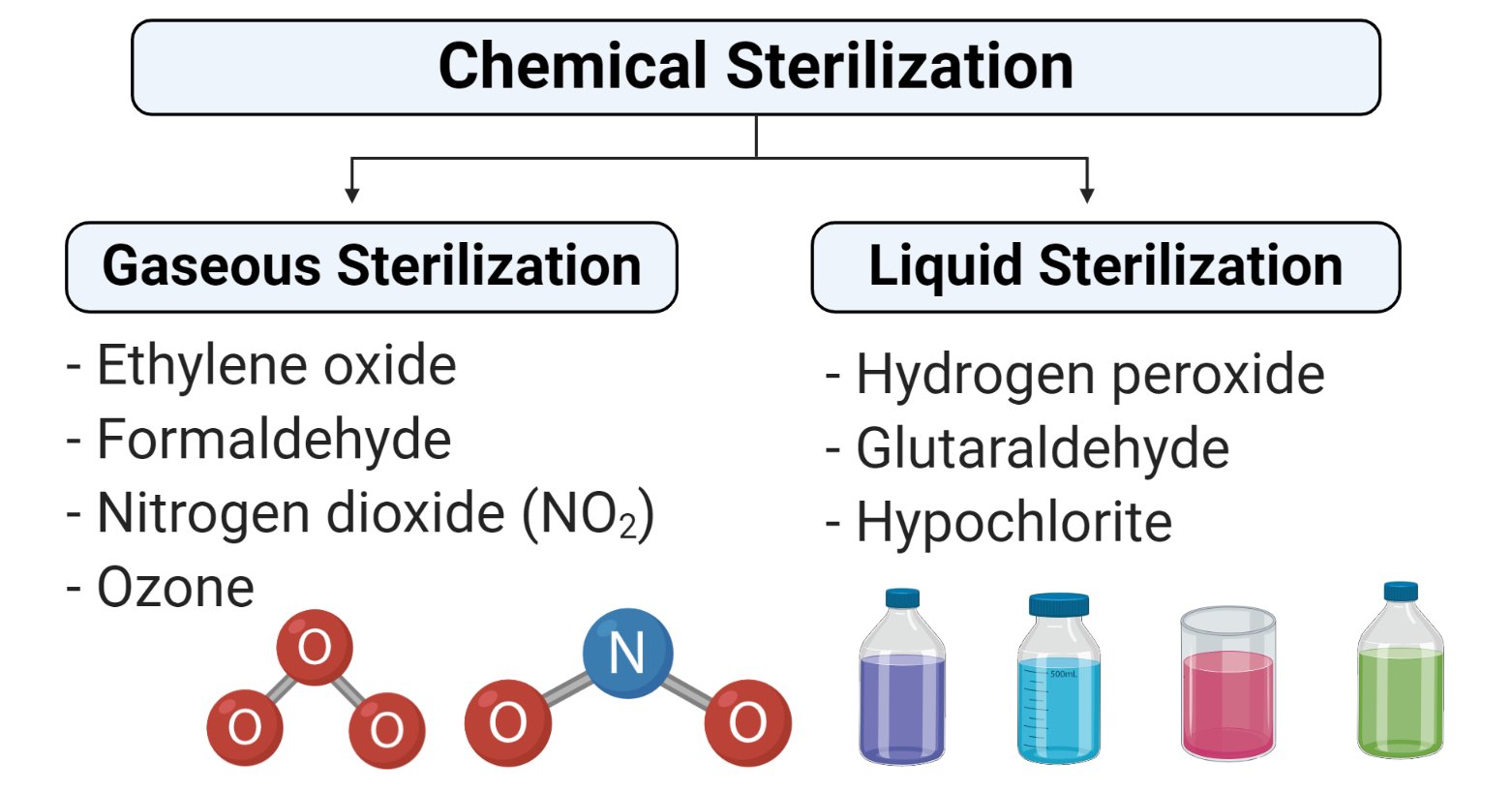

DISINFECTION METHODS: Its Advantages and disadvantages

Advantages and Disadvantages MS ELAINE M A water treatment processes designed to destroy DISINFECTANTS USED FOR CHEMICAL disinfection |

|

Download PDF

31 juil 2018 · rent wastewater treatment methods involve a combination of physical, chemical and biological processes, and operations to remove insoluble |

|

Chemical Precipitation - US EPA

amount of chemicals required for treatment depends understand the advantages and disadvantages of this Some treatment chemicals, especially lime, |

|

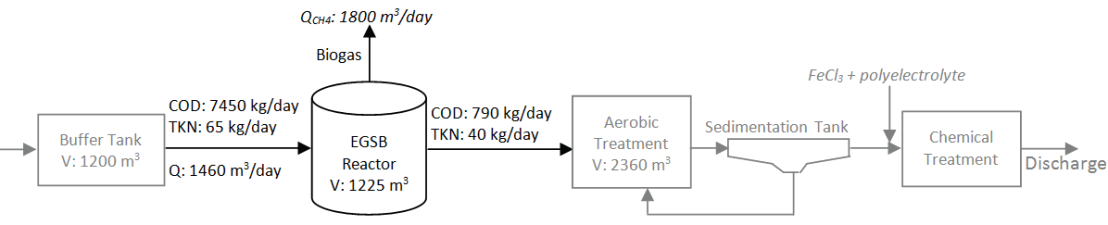

Wastewater Treatment Methods for Effluents from the Confectionery

It is characterized by high values of chemical oxygen demand (COD) and biological The advantages and disadvantages of the biological treatment under |

|

Advanced Electrochemical Technologies in Wastewater Treatment

commonly used chemical process in many industrial wastewater treatment conventional wastewater treatment technologies have some disadvantages such |

|

Coagulation and flocculation - DWQR

The addition of a chemical coagulant to the water causes the The principal disadvantages of using coagulants for treatment of small supplies are the cost and |

|

Wastewater treatment technologies

selection of the best treatment technology and the most appropriate technical solution Mechanical systems utilize a combination of physical, biological, and chemical Advantages and Disadvantages of Conventional and Non- conventional |

![PDF] Advantages and disadvantages of healthcare waste treatment PDF] Advantages and disadvantages of healthcare waste treatment](https://d3i71xaburhd42.cloudfront.net/32dca140fb3bbdcdb67aa4eec9ce01b052919bac/3-Figure1-1.png)

![PDF] Advantages and disadvantages of techniques used for PDF] Advantages and disadvantages of techniques used for](https://i1.rgstatic.net/publication/235294430_Chemical_Treatment_of_Industrial_Wastewater/links/5b72b008299bf14c6da1a3ab/largepreview.png)

![PDF] Physico-chemical Treatment of Oil Palm Biomass into PDF] Physico-chemical Treatment of Oil Palm Biomass into](https://img.yumpu.com/12351205/1/500x640/ptcy-9111pdf.jpg)

![PDF] Advantages and disadvantages of healthcare waste treatment PDF] Advantages and disadvantages of healthcare waste treatment](https://i1.rgstatic.net/publication/228724404_Chlorine_Is_it_really_so_bad_and_what_are_the_alternatives/links/0046352303d3b28245000000/largepreview.png)

![PDF] Advantages and disadvantages of healthcare waste treatment PDF] Advantages and disadvantages of healthcare waste treatment](https://www.intechopen.com/media/chapter/49024/media/image9.png)

![PDF] Wood preservation and wood products treatment : training PDF] Wood preservation and wood products treatment : training](https://www.intechopen.com/media/chapter/49024/media/fig55.png)